Production

The precision and flexibility of Bozzi S.p.A.’s productions are confirmed by the experience gained in multiple sectors that include various types of processing. Materials and types of processed products undergo thorough testing and studies to ensure maximum results for the customer. Bozzi S.p.A. is capable of providing finished products, including the purchase of raw materials and, where necessary, heat and/or surface treatments, relying for years on suitably qualified partners. The materials primarily used in the manufacturing of parts include:

– Aluminum Alloys

– Construction Steels

– Stainless Steels (austenitic, ferritic, martensitic)

– Precipitation Hardening Stainless Steels

– Titanium Alloys

– Bronze, Brass

– Inconel Alloys and Superalloys

– Plastic Materials: Nylon, PVC, Delrin, Teflon, etc.

Our

Technology

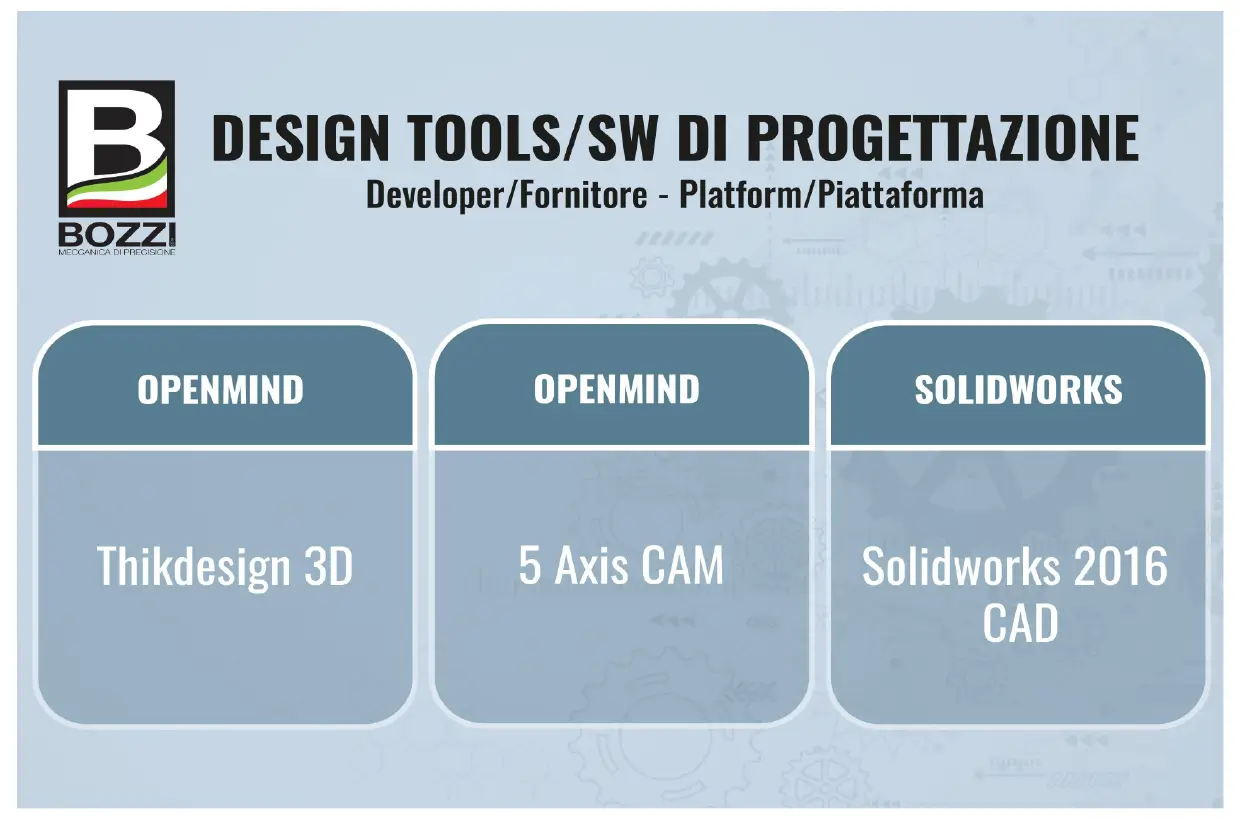

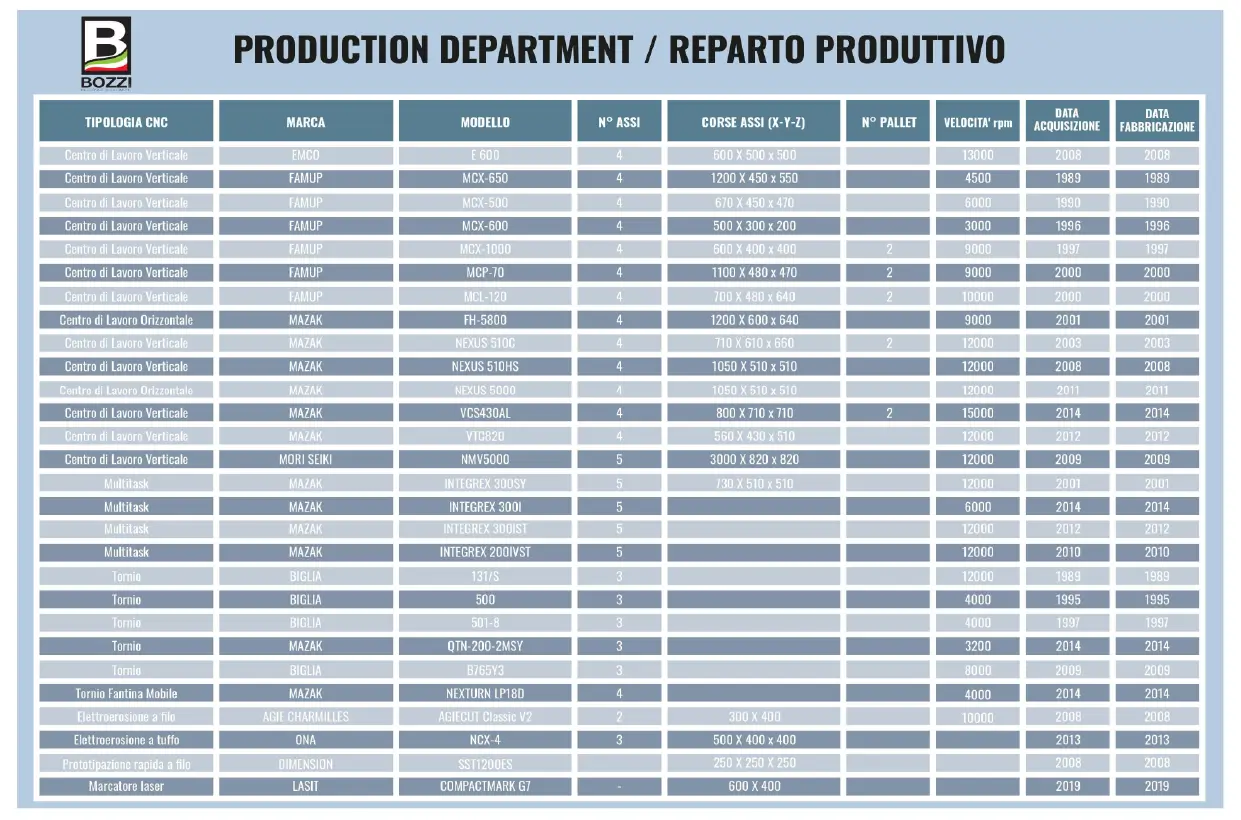

Over the years, progress and innovation have led to the introduction and use of new CAD CAM systems with 5-axis technology. With the adoption of these software, the company has increased the level of difficulty and precision of the processes that can be carried out.The technological park of chip removal machines has made significant advances over the years, following the purchase of high-precision machinery such as a Moriseiki 5-axis, 10 Mazak horizontal and vertical centers, 3 multi-task machines (Mazak Integrex), and most recently, an AgieChermille wire EDM and a plunge EDM, which have strengthened the company fleet, enabling Bozzi to achieve many goals.

To support its process phases, the metrology control department has been significantly enhanced with the introduction over time of 3 new 3D measuring machines, necessary for the most complex testing operations. Additionally, the department boasts a top-tier range of instruments, including height gauges, profilometers, durometers, and every type of manual instrument.

Some

Curiosity

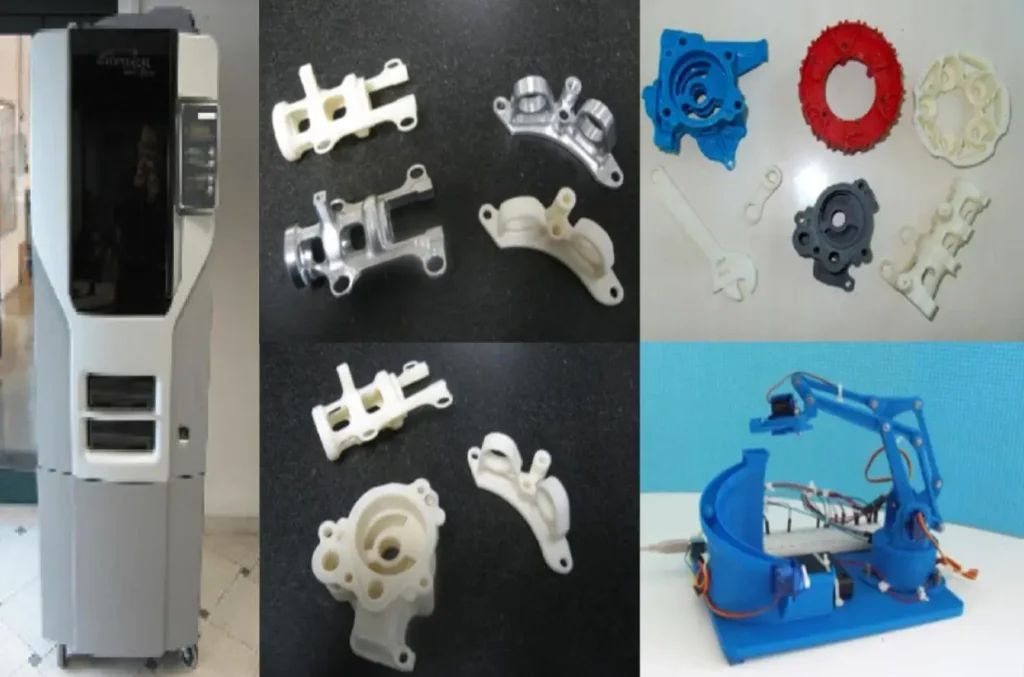

Bozzi S.p.A. also offers customers solutions in RP (Rapid Prototyping), following the acquisition of a 3D printer (250mm x 250mm H300mm) capable of transforming a 3D CAD model into a solid ABS component. This methodology can therefore provide conceptual, functional, and technical results, for example, in pre-series operations.

Since 2019, Bozzi S.p.A. has been utilizing a “CompactMark G7” laser marking machine. At the top of its class on the market, it can engrave any text in linear, angled, or curved styles, images, BAR codes, and QR codes, on any material and on flat or curved surfaces, whether they are finely finished or rough. The marking machine has a working table size of 800x450mm with a height of 400mm and is equipped with a removable motorized spindle.